Arable Farming

We farm about 3200 acres of arable 200 acres of grassland and 200 acres of Countryside Stewardships and Game cover.

Cultivations

We moved away from ploughing in the early 1990s. We bought a big Case QuadTrac , matched it with various min-till cultivators usually a multi-tool train which did discing, sub soiling and rolling in one pass. These including Simba Solo and the Simba SL700. We tried other machines like the Topdown and the Rexis Twin as well. We tended to run smaller discs like the Carrier, as well as a Spring tines cultivator of one make or another.

Today we run a Weeving 5m LD. This is a low disturbance sub soiler which we use roughly 2 out of every 4 years across our rotation. At 0.5m spacing and a low disturbance point we are not aiming to move soil but to crack it and fracture it so that any pans in the soil are broken or cracked. We still run a Carrier disc (where appropriate) at 1 inch, to create a chit of weeds and crush slugs. We then roll, and leave the seed bed for drilling.

Drilling

We have drilled with our Bateman drill for over 30 years now. It has come in several versions; the first being adapted from a basic Accord tine system, which changed in about 2003 to the Horsh Pronto disc system, and now because of black grass forcing us into later drilling we have wetter seedbeds, so we are back to a tine drill in the form of the Weeving Sabre tine. The original version of the drill was built and designed by Jason Bateman and his father. Darren who works on the farm adapted the drill to its new shape in with the Pronto back end and then Jason went back to the drawing board and recreated and new tool bar for carrying the sabre tines in 2022.

We are always wanting to get the most productivity out of our machines and by using the chassis of our Bateman we are able to do that. The key is output. If you will be needing to do pre-emergence sprays whilst you are drilling then you will not be able to make this system work. We can comfortably drill 200 acres per day with this drill. We have roughly 1000 acres of wheat so it should take 5 days to drill. That is plenty of time to get the rolls over the ground, put the sprayer back on and spray it. It takes 15 minutes to take the drill off and another 15 minutes to put the sprayer back on..

The Sabre tine allows us the flexibility of drilling directly if required which we do with our cover crops, our oil seed rape and some of our wheat. We also drill our spring barley directly into our cover cropped ground (so approximately 50% of the farm). We use variable seed rates through our SOYL “My Farm” program.

We drill the majority of our rape with either the Bateman directly or the Cousins Micro Wing which allows us to put seed, fertiliser, slug pellets and a companion crop in all in one direct pass. It is on 0.6m spacings.

Spraying

We spray with our 40m Bateman sprayer. We use the Altec nozzle system which allows us to use a combination of up to 4 nozzles spraying at any one time. This allows the best coverage and creates more spraying windows of opportunity.

We house our sprayer inside so that it stays frost free, and also it prevents rain run-off of any residual chemicals accidently sprayed on to itself. In that sprayer shed we run a mixing plant. In here someone (usually me) will pre-mix the next spray mix for Darren (the spray operator). An agreed spray plan at the start of the day taking into consideration herbicides, compatibility and the geography. It will allow us to comfortably cover 300 hectares per day. Darren will pull in and with our 1000 litre a minute pump he can put the next load in and be on his way again six minutes later. We have satellite guidance, auto section control, NORAC auto boom levelling control and infrared CropSPec.

Fertiliser

We use liquid fertiliser for all our crops, usually a heavy Nitrogen base with a bit of sulphur added. These are stored in several strategically placed tanks around the farms. We persuaded Bateman to change the pump to a central fugal pump that can draw the fertiliser out of the tanks through a filter quickly. We used to run a milk tanker bowser system but we have found this new method to be quicker.

Solid fertilisers usually in the form of Muriate of Potash and Tripple Super Phosphates are applied using a spinner on the back of the Bateman. Again here we run a back up system. The man on the loader has a hopper with a trap door in the bottom which we designed and BK Grain fabricated for us so that when the spinner is empty the loader driver who has pre-loaded the hopper with the correct fertiliser will simply drive up the to the spinner put the hopper over the spinner hopper and press a button. Two tonnes will fall straight into the spinner in 10 seconds and the Bateman can be on its way again. We use the same hopper for backing up the seed drill in the same fashion.

We use a “CropSpec” precision, real time variable rate nitrogen application system with auto section cut off to reduce overlaps and apply precisely what the crop needs.

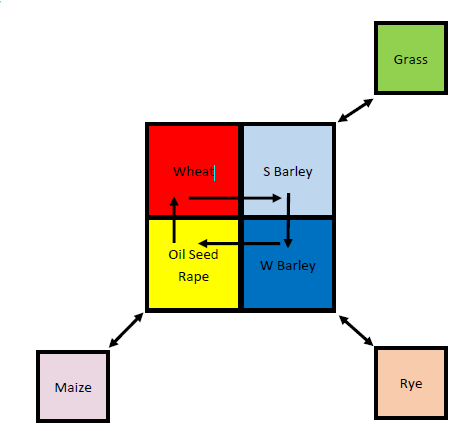

Crop Rotations

We generally run a simple 4 crop rotation Wheat to Spring Barley to Winter Barley to Oil Seed Rape then back to Wheat but we also throw in Maize, Rye and Grass leys. We include in the grass leys 100 acres of AB15 the we rotate around the farm as part of our Re-gen policy towards our soils.

Like all farms we are looking for the illusive break crop that is profitable and will enhance the quality of our soils. Rye is a good rooter, maize is poor in most ways but a good clean weed free break and grass will be revolved around the farm as the cattle enterprise requires it.